Search This Supplers Products:PCB AssemblyPCB QuotePrinted Circuit BoardPCB Board

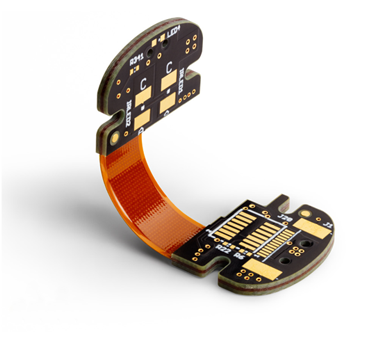

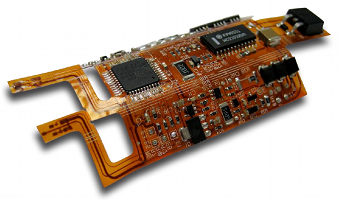

Double-sided Flexible PCB (FPC) Screen Printing Technology

time2018/09/28

- In the process of manufacturing flexible circuit boards, screen printing is usually used, which is often used when printing single-sided printed circuit boards. The number of printed double-sided boards is small, but the number of printed double-sided rigid PCB boards is a lot.

In the process of manufacturing flexible circuit boards, screen printing is usually used, which is often used when printing single-sided printed circuit boards. The number of printed double-sided boards is small, but the number of printed double-sided rigid PCB boards is a lot.

It can be seen that the production of flexible circuit boards by printing is relatively popular, but due to market factors, the cost of production is different. For a double-sided flexible circuit board, the printing principle is the same as that of a general rigid printed circuit board. If a rigid circuit board is to be printed, for the conduction of two layers of lines, a copper sink can be used. In the case of a double-sided flexible circuit board, the conduction of the two-layer circuit mainly uses silver ink, which penetrates from the small hole, and the upper and lower layers of the circuit board are filled, so that the processing is completed. However, in the actual processing, in order to ensure the quality, it is necessary to analyze the matters to be noticed in the screen printing of the double-sided flexible circuit board using carbon ink as the conductive ink.

It can be seen that the production of flexible circuit boards by printing is relatively popular, but due to market factors, the cost of production is different. For a double-sided flexible circuit board, the printing principle is the same as that of a general rigid printed circuit board. If a rigid circuit board is to be printed, for the conduction of two layers of lines, a copper sink can be used. In the case of a double-sided flexible circuit board, the conduction of the two-layer circuit mainly uses silver ink, which penetrates from the small hole, and the upper and lower layers of the circuit board are filled, so that the processing is completed. However, in the actual processing, in order to ensure the quality, it is necessary to analyze the matters to be noticed in the screen printing of the double-sided flexible circuit board using carbon ink as the conductive ink.

Analysis of the main points of the upper layer double-sided flexible circuit board screen printing technology

Before the screen printing, select the materials to be used first, and pre-treat the materials in advance, so that the shrinkage deformation problem will not occur in the screen printing. Otherwise, many problems will occur in the subsequent processing, which directly affects the screen printing quality. In order to meet the design requirements, some dimensional accuracy on the double-sided flexible PCB is very high. It can be numbered as A, and it can be distinguished from the lower line B. Generally, the carbon-ink material net is used to print the A-side line. In the screen printing operation, the thickness of the ink must be controlled. After the ink thickness reaches the design requirements, the requirements of the entire line for resistance can be achieved to ensure normal afterwards use.

Analyze the points to pay attention to when punching and filling carbon holes

Based on the previous work experience, the diameter of the carbon hole is generally in the range of 0.8 to 1.0 mm. In the process of filling the carbon hole, the size of the hole must be appropriate. If the carbon hole is too large, the screen printing process of the lower layer is performed.

If there is too much carbon ink permeating through the carbon filling hole, the remaining ink will flow through the carbon filling hole. This kind of ink is not cleaned. If it cannot be completely removed, it will remain on the screen printing table for a long time, which not only affects the overall beauty, it is also easy to cause short circuit problems on the line.

If there is too much carbon ink permeating through the carbon filling hole, the remaining ink will flow through the carbon filling hole. This kind of ink is not cleaned. If it cannot be completely removed, it will remain on the screen printing table for a long time, which not only affects the overall beauty, it is also easy to cause short circuit problems on the line.

In addition, the width of the line is limited, so the size of the carbon hole cannot exceed this width range. If the diameter of the carbon filling hole is too small, there are certain problems, and there are great difficulties in making the stamping die later, and generally it is selected. PET as a material, after the completion of the punching and filling of the carbon hole, the blanking is not easy to fall off, and only the artificial peeling method can be used. Otherwise, the carbon filling hole will be covered in the next process, which is not conducive to the effective flow of the ink, directly leading to the upper layer and the lower layer. There is an obstacle in the continuity of the line.

On the other hand, when the carbon-filled holes are too small, the amount of ink that is transmitted is small, and the upper and lower layers are not easily turned on. For this case, the upper line surface must be considered when punching the carbon-filled holes. It is required to always face upwards. The main purpose is to make the serrated protrusions, flash edges, etc. face the unprinted side, which is beneficial to the next process.

In order to increase the probability of conduction of the two layers, a carbon filling hole can be added at the same point. The specific distance set should be determined according to the actual width, and should not be too large or too small. Generally, the carbon filling holes are relatively small, and the distance between them is relatively close. It is very difficult to make a stamping die. The general technician will make two sets of molds. In the stamping process, one small hole can be punched at a time, that is, half of the carbon holes are poured. It is realized in two parts and achieves a good effect.

Analysis of the precautions for screen printing lower layer lines

In the process of screen printing, the positioning hole is used as the reference, and the layer line is printed on the side that has not been screen printed. As mentioned above, the draping faces all toward the B side, so after finishing the screen printing work, the draping is also covered. A layer of ink, after the screen printing is completed, it has a strong fluidity due to the action of gravity, so that the carbon ink is easy to permeate the carbon filling hole, and finally is well connected with the upper layer line, so that the A side and the B side are It is very good to complete the conduction, but if the slanting face is facing the A side, the ink will flow through the carbon filling hole to the A surface line when the screen is printed on the B side. Under the blocking action of the cloak, the embossing height h can be set, so that the ink If you do not agree to flow through the cloak, you will not be able to communicate well with A. It can be seen that in this case, the A-layer line and the B-layer line are basically impossible to conduct. The fluidity of the screen printed conductive ink is also important for the conduction of the carbon-filled holes. Generally, the inks used are relatively viscous, and the actual fluidity is poor, resulting in a low probability that the upper layer and the lower layer can be turned on. When printing, when using the machine printing method, the vacuum suction device is used on the workbench, which improves the fluidity of the conductive ink, but this measure also has a drawback, that is, it will remain on the workbench after operation. A large amount of ink, if the residual ink is not removed in time, will lead to the deterioration of the quality of the line. When the manual printing method is adopted, the vacuum suction device is not installed on the workbench, and after the screen printing operation of the line is completed, the actual combination is required. In the case, the board is placed for a period of time, and then placed in a drying oven for drying, so that the ink can flow sufficiently, so that the upper line and the lower line are well turned on. However, the thickness of the ink must be effectively controlled during the specific screen printing, so that the line resistance value and the design are consistent.

After the above work is completed, the final shape stamping operation should be completed, and the product should be inspected at the same time. According to the use of the circuit board, it is required to reach the designed external dimension in the stamping process, and finally the line test is performed, and the short circuit problem cannot occur. There is also no short-circuit problem, and whether the resistance value meets the design requirements. After these aspects are all qualified, the double-sided flexible circuit board is screen printed. In view of the problems in the screen printing of double-sided flexible circuit boards, effective solutions are proposed to ensure the quality of processing. Due to the different materials, design forms, and uses, in order to design a circuit board that meets the requirements, technicians must coordinate and master relevant knowledge, propose effective methods to deal with problems, optimize production and processing technology, and integrate new technologies in time. Further improve the quality of China's double-sided flexible circuit board screen printing technology, and occupy an advantage in international competition.